- Size: 4mm to 130mm outer diameter

- Material:E355 (ST52.4),E235 (ST37.4)

- Standard:DIN 2391/C (DIN EN 10305-1),DIN 2445/2 (DIN EN 10305-4)

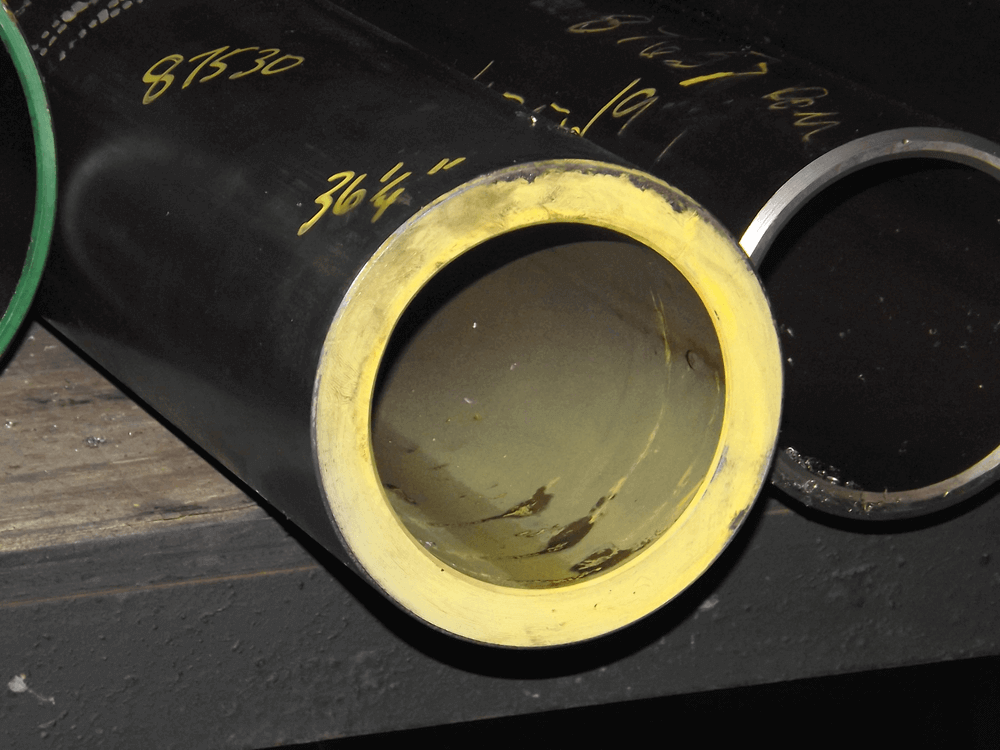

- Finishing:NBK (Phosphate and Normalized)

Seamless hydraulic tube is designed to convey liquid fluids to among hydraulics components, fittings, valves, flanges, and other tools. It is made of material E355 (ST 52.4) or E235 (ST 37.4). These two grades have different chemical composition. This helps to control the working pressure.

|

Chemical Composition (%)

|

Carbon (C)

|

Silicon (Si)

|

Manganese (Mn)

|

Phosphorus (P)

|

Sulfur (S)

|

|

E355 (ST52.4)

|

⩽ 0.22

|

⩽ 0.55

|

⩽ 1.6

|

⩽ 0.045

|

⩽ 0.045

|

|

E235 (ST37.4)

|

⩽ 0.17

|

⩽ 0.35

|

⩽ 1.2

|

⩽ 0.045

|

⩽ 0.045

|

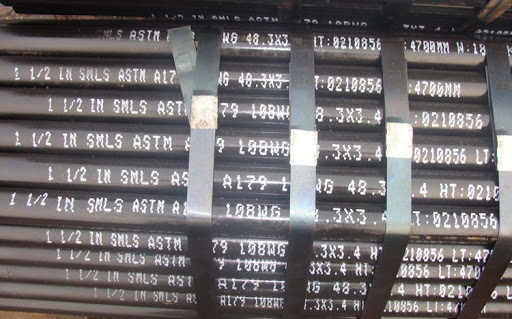

Seamless hydraulic tube is made according to DIN 2391/C (DIN EN 10305-1) or DIN 2445/2 (DIN EN 10305-4) standards and it is available in millimeters, inches outer diameter, and inches nominal bore size.

How to make Seamless hydraulic tube

The tubes surface finishing is NBK, where the tubes are phosphate and normalized which provides corrosion resistance. It is oiled inside and outside. Normalize process creates tougher metal product. During normalizing, metals will be heated at a high temperature, and it allowed to naturally cool back down to room temperature by exposure after heating. Metals that have been through this process are more formable, harder and ductile.

Pressure ratings of Seamless hydraulic tube

Allowable working pressures are calculated using as per DIN 2413 at normal temperature. The yield and tensile stress values utilize to determine the maximum allowable running pressure and wall thickness required. The tubes and pipes are delivered the actual yield and tensile stress values are verified from the true copy material certificates. Pressure reduction factors at various temperatures show below:

|

° C

|

-40

|

120

|

150

|

175

|

200

|

250

|

|

° F

|

-40

|

248

|

302

|

347

|

392

|

482

|

|

Rating Factor

|

0.90

|

1.0

|

0.89

|

0.89

|

0.83

|

NA

|

Seamless hydraulic tube (ST37.4 NBK) Working Pressure Table:

|

No. |

Description |

Working Pressure (Bar) |

Burst Pressure (Bar) |

IMPA CODE |

|

1 |

4MM OD x 1.0MM THK x 6 MTR |

707 |

1755 |

710701 |

|

2 |

5MM OD x 1.0MM THK x 6 MTR |

565 |

1404 |

- |

|

3 |

6MM OD x 1.0MM THK x 6 MTR |

471 |

1170 |

710702 |

|

4 |

6MM OD x 1.5MM THK x 6 MTR |

707 |

1755 |

710703 |

|

5 |

8MM OD x 1.0MM THK x 6 MTR |

353 |

878 |

710704 |

|

6 |

8MM OD x 1.5MM THK x 6 MTR |

530 |

1316 |

710705 |

|

7 |

8MM OD x 2.0MM THK x 6 MTR |

707 |

1755 |

710706 |

|

8 |

8MM OD x 2.5MM THK x 6 MTR |

883 |

2194 |

- |

|

9 |

10MM OD x 1.0MM THK x 6 MTR |

283 |

702 |

710707 |

|

10 |

10MM OD x 1.2MM THK x 6 MTR |

339 |

845 |

710708 |

|

11 |

10MM OD x 1.5MM THK x 6 MTR |

424 |

1053 |

710709 |

|

12 |

10MM OD x 2.0MM THK x 6 MTR |

565 |

1404 |

710710 |

|

13 |

10MM OD x 2.5MM THK x 6 MTR |

707 |

1755 |

- |

|

14 |

12MM OD x 1.0MM THK x 6 MTR |

236 |

585 |

710711 |

|

15 |

12MM OD x 1.2MM THK x 6 MTR |

283 |

702 |

710712 |

|

16 |

12MM OD x 1.5MM THK x 6 MTR |

353 |

878 |

710713 |

|

17 |

12MM OD x 2.0MM THK x 6 MTR |

471 |

1170 |

710714 |

|

18 |

12MM OD x 2.5MM THK x 6 MTR |

589 |

1463 |

- |

|

19 |

12MM OD x 3.0MM THK x 6 MTR |

707 |

1755 |

- |

|

20 |

14MM OD x 1.5MM THK x 6 MTR |

303 |

752 |

- |

|

21 |

14MM OD x 2.0MM THK x 6 MTR |

404 |

1003 |

- |

|

22 |

14MM OD x 2.5MM THK x 6 MTR |

505 |

1254 |

- |

|

23 |

14MM OD x 3.0MM THK x 6 MTR |

606 |

1504 |

- |

|

24 |

14MM OD x 4.0MM THK x 6 MTR |

807 |

2006 |

- |

|

25 |

15MM OD x 1.0MM THK x 6 MTR |

188 |

468 |

- |

|

26 |

15MM OD x 1.2MM THK x 6 MTR |

226 |

562 |

710715 |

|

27 |

15MM OD x 1.5MM THK x 6 MTR |

283 |

702 |

710716 |

|

28 |

15MM OD x 2.0MM THK x 6 MTR |

377 |

936 |

710717 |

|

29 |

15MM OD x 2.5MM THK x 6 MTR |

471 |

1170 |

710718 |

|

30 |

15MM OD x 3.0MM THK x 6 MTR |

565 |

1404 |

- |

|

31 |

16MM OD x 1.5MM THK x 6 MTR |

265 |

658 |

710719 |

|

32 |

16MM OD x 2.0MM THK x 6 MTR |

353 |

878 |

710720 |

|

33 |

16MM OD x 3.0MM THK x 6 MTR |

530 |

1316 |

- |

|

34 |

18MM OD x 1.5MM THK x 6 MTR |

236 |

585 |

710721 |

|

35 |

18MM OD x 2.0MM THK x 6 MTR |

314 |

780 |

710722 |

|

36 |

18MM OD x 2.5MM THK x 6 MTR |

393 |

975 |

710723 |

|

37 |

18MM OD x 3.0MM THK x 6 MTR |

471 |

1170 |

- |

|

38 |

20MM OD x 2.0MM THK x 6 MTR |

283 |

702 |

710724 |

|

39 |

20MM OD x 2.5MM THK x 6 MTR |

353 |

878 |

710725 |

|

40 |

20MM OD x 3.0MM THK x 6 MTR |

424 |

1053 |

710726 |

|

41 |

20MM OD x 3.5MM THK x 6 MTR |

495 |

1229 |

- |

|

42 |

20MM OD x 4.0MM THK x 6 MTR |

565 |

1404 |

- |

|

No. |

Description |

Working Pressure (Bar) |

Burst Pressure (Bar) |

IMPA CODE |

|

43 |

20MM OD x 4.5MM THK x 6 MTR |

636 |

1580 |

- |

|

44 |

20MM OD x 5.0MM THK x 6 MTR |

707 |

1755 |

- |

|

45 |

22MM OD x 2.0MM THK x 6 MTR |

257 |

638 |

710727 |

|

46 |

22MM OD x 2.5MM THK x 6 MTR |

321 |

798 |

- |

|

47 |

22MM OD x 3.0MM THK x 6 MTR |

385 |

957 |

710728 |

|

48 |

22MM OD x 4.0MM THK x 6 MTR |

514 |

1276 |

- |

|

49 |

25MM OD x 2.0MM THK x 6 MTR |

226 |

562 |

710729 |

|

50 |

25MM OD x 2.5MM THK x 6 MTR |

283 |

702 |

710730 |

|

51 |

25MM OD x 3.0MM THK x 6 MTR |

339 |

842 |

710731 |

|

52 |

25MM OD x 3.5MM THK x 6 MTR |

396 |

983 |

- |

|

53 |

25MM OD x 4.0MM THK x 6 MTR |

452 |

1123 |

- |

|

54 |

25MM OD x 5.0MM THK x 6 MTR |

565 |

1404 |

- |

|

55 |

28MM OD x 2.0MM THK x 6 MTR |

202 |

501 |

- |

|

56 |

28MM OD x 2.5MM THK x 6 MTR |

252 |

627 |

710732 |

|

57 |

28MM OD x 3.0MM THK x 6 MTR |

303 |

752 |

- |

|

58 |

28MM OD x 4.0MM THK x 3 MTR |

404 |

1003 |

- |

|

59 |

28MM OD x 5.0MM THK x 6 MTR |

505 |

1254 |

- |

|

60 |

30MM OD x 2.0MM THK x 6 MTR |

188 |

468 |

- |

|

61 |

30MM OD x 2.5MM THK x 6 MTR |

236 |

585 |

710733 |

|

62 |

30MM OD x 3.0MM THK x 6 MTR |

283 |

702 |

- |

|

63 |

30MM OD x 4.0MM THK x 6 MTR |

377 |

936 |

- |

|

64 |

30MM OD x 5.0MM THK x 6 MTR |

471 |

1170 |

- |

|

65 |

35MM OD x 2.0MM THK x 6 MTR |

161 |

401 |

- |

|

66 |

35MM OD x 2.5MM THK x 6 MTR |

202 |

501 |

710734 |

|

67 |

35MM OD x 3.0MM THK x 6 MTR |

242 |

602 |

- |

|

68 |

35MM OD x 4.0MM THK x 6 MTR |

323 |

802 |

710735 |

|

69 |

35MM OD x 5.0MM THK x 6 MTR |

404 |

1003 |

- |

|

70 |

38MM OD x 3.0MM THK x 6 MTR |

223 |

554 |

- |

|

71 |

38MM OD x 4.0MM THK x 6 MTR |

297 |

739 |

- |

|

72 |

38MM OD x 5.0MM THK x 6 MTR |

372 |

924 |

- |

|

73 |

42MM OD x 2.0MM THK x 6 MTR |

135 |

334 |

- |

|

74 |

42MM OD x 3.0MM THK x 6 MTR |

202 |

501 |

- |

|

75 |

42MM OD x 4.0MM THK x 6 MTR |

269 |

669 |

710736 |

|

76 |

42MM OD x 5.0MM THK x 6 MTR |

336 |

836 |

- |

|

77 |

50MM OD x 3.0MM THK x 6 MTR |

170 |

421 |

- |

|

78 |

50MM OD x 5.0MM THK x 6 MTR |

283 |

702 |

- |

|

79 |

60MM OD x 3.0MM THK x 6 MTR |

141 |

351 |

- |

|

80 |

60MM OD x 5.0MM THK x 6 MTR |

236 |

585 |

- |

|

81 |

65MM OD x 6.0MM THK x 6 MTR |

261 |

648 |

- |

|

82 |

75MM OD x 3.0MM THK x 6 MTR |

113 |

281 |

- |

|

83 |

1/8"NB x 2.41MM THK x 6 MTR |

649 |

1611 |

- |

|

84 |

1/4"NB x 3.02MM THK x 6 MTR |

618 |

1536 |

- |

|

No. |

Description |

Working Pressure (Bar) |

Burst Pressure (Bar) |

IMPA CODE |

|

85 |

3/8"NB x 3.2MM THK x 6 MTR |

523 |

1298 |

- |

|

86 |

1/2"NB x 3.0MM THK x 6 MTR |

391 |

971 |

- |

|

87 |

3/4"NB x 3.0MM THK x 6 MTR |

312 |

774 |

- |

|

88 |

1"NB x 3.5MM THK x 6 MTR |

291 |

723 |

- |

|

89 |

1"NB x 4.55MM THK x 6 MTR |

378 |

939 |

- |

|

90 |

1 1/4"NB x 4.85MM THK x 6 MTR |

321 |

797 |

- |

|

91 |

1 1/2"NB x 5.08MM THK x 6 MTR |

295 |

734 |

- |

|

92 |

2 1/2"NB x 6.3MM THK x 6 MTR |

NIL |

580 |

- |

|

93 |

1/4"OD x 1.2MM THK x 6 MTR |

534 |

1327 |

- |

|

94 |

1/4"OD x 1.5MM THK x 6 MTR |

668 |

1658 |

- |

|

95 |

3/8"OD x 1.22MM THK x 6 MTR |

362 |

899 |

- |

|

96 |

3/8"OD x 1.5MM THK x 6 MTR |

445 |

1105 |

- |

|

97 |

1/2"OD x 1.5MM THK x 6 MTR |

334 |

829 |

- |

|

98 |

3/4"OD x 2.0MM THK x 6 MTR |

297 |

737 |

- |

|

99 |

3/4"OD x 2.64MM THK x 6 MTR |

392 |

973 |

- |

|

100 |

1"OD x 3.0MM THK x 6 MTR |

334 |

829 |

- |

|

101 |

1 1/4"OD x 3.0MM THK x 6 MTR |

267 |

663 |

- |

|

102 |

1 1/4"OD x 3.25MM THK x 6 MTR |

289 |

719 |

- |

Hydraulic Tube (ST52.4 NBK) Working Pressure Table:

|

No. |

Description |

Working Pressure (Bar) |

Burst Pressure (Bar) |

IMPA CODE |

|

103 |

10MM OD x 2.0MM THK x 6 MTR |

799 |

1919 |

710710 |

|

104 |

12MM OD x 2.0MM THK x 6 MTR |

666 |

1599 |

710714 |

|

105 |

14MM OD x 1.5MM THK x 6 MTR |

428 |

1028 |

- |

|

106 |

14MM OD x 2.0MM THK x 6 MTR |

571 |

1371 |

- |

|

107 |

15MM OD x 1.5MM THK x 6 MTR |

400 |

959 |

710716 |

|

108 |

15MM OD x 2.0MM THK x 6 MTR |

533 |

1279 |

710717 |

|

109 |

15MM OD x 2.5MM THK x 6 MTR |

666 |

1599 |

710718 |

|

110 |

16MM OD x 1.5MM THK x 6 MTR |

375 |

899 |

710719 |

|

111 |

16MM OD x 2.0MM THK x 6 MTR |

500 |

1199 |

710720 |

|

112 |

16MM OD x 3.0MM THK x 6 MTR |

749 |

1799 |

- |

|

113 |

18MM OD x 1.5MM THK x 6 MTR |

333 |

800 |

710721 |

|

114 |

18MM OD x 2.0MM THK x 6 MTR |

444 |

1066 |

710722 |

|

115 |

20MM OD x 2.0MM THK x 6 MTR |

400 |

959 |

710724 |

|

116 |

20MM OD x 2.5MM THK x 6 MTR |

500 |

1199 |

710725 |

|

117 |

20MM OD x 3.0MM THK x 6 MTR |

599 |

1439 |

710726 |

|

118 |

22MM OD x 2.0MM THK x 6 MTR |

363 |

872 |

710727 |

|

119 |

25MM OD x 2.0MM THK x 6 MTR |

320 |

768 |

710729 |

|

120 |

25MM OD x 2.5MM THK x 6 MTR |

400 |

959 |

710730 |

|

121 |

25MM OD x 3.0MM THK x 6 MTR |

480 |

1151 |

710731 |

|

122 |

25MM OD x 4.0MM THK x 6 MTR |

639 |

1535 |

- |

|

123 |

25MM OD x 5.0MM THK x 6 MTR |

799 |

1919 |

- |

|

124 |

28MM OD x 2.0MM THK x 6 MTR |

285 |

685 |

- |

|

125 |

28MM OD x 3.0MM THK x 6 MTR |

428 |

1028 |

- |

|

126 |

30MM OD x 2.0MM THK x 6 MTR |

266 |

640 |

- |

|

127 |

30MM OD x 3.0MM THK x 6 MTR |

400 |

959 |

- |

|

128 |

30MM OD x 4.0MM THK x 6 MTR |

533 |

1279 |

- |

|

129 |

35MM OD x 3.0MM THK x 6 MTR |

343 |

822 |

- |

|

130 |

35MM OD x 4.0MM THK x 6 MTR |

457 |

1096 |

710735 |

|

131 |

38MM OD x 3.0MM THK x 6 MTR |

315 |

757 |

- |

|

132 |

38MM OD x 4.0MM THK x 6 MTR |

421 |

1010 |

- |

|

133 |

38MM OD x 5.0MM THK x 6 MTR |

526 |

1262 |

- |

|

134 |

42MM OD x 3.0MM THK x 6 MTR |

285 |

685 |

- |

|

135 |

42MM OD x 4.0MM THK x 6 MTR |

381 |

914 |

710736 |

|

136 |

42MM OD x 5.0MM THK x 6 MTR |

476 |

1142 |

- |

|

137 |

45MM OD x 5.0MM THK x 6 MTR |

444 |

1066 |

- |

|

138 |

50MM OD x 5.0MM THK x 6 MTR |

400 |

959 |

- |

|

139 |

50MM OD x 6.0MM THK x 6 MTR |

480 |

1151 |

- |

|

140 |

50MM OD x 10.0MM THK x 6 MTR |

799 |

1919 |

- |

|

141 |

54MM OD x 6.0MM THK x 6 MTR |

444 |

1066 |

- |

|

142 |

60MM OD x 5.0MM THK x 6 MTR |

333 |

800 |

- |

|

143 |

60MM OD x 6.0MM THK x 6 MTR |

400 |

959 |

- |

|

No. |

Description |

Working Pressure (Bar) |

Burst Pressure (Bar) |

IMPA CODE |

|

144 |

65MM OD x 8.0MM THK x 6 MTR |

492 |

1181 |

- |

|

145 |

66MM OD x 8.5MM THK x 6 MTR |

515 |

1236 |

- |

|

146 |

76.1MM OD x 6.3MM THK x 6 MTR |

331 |

794 |

- |

|

147 |

80MM OD x 10.0MM THK x 6 MTR |

500 |

1199 |

- |

|

148 |

90MM OD x 5.0MM THK x 6 MTR |

222 |

533 |

- |

|

149 |

90MM OD x 10.0MM THK x 6 MTR |

444 |

1066 |

- |

|

150 |

97MM OD x 12.0MM THK x 6 MTR |

494 |

1187 |

- |

|

151 |

100MM OD x 10.0MM THK x 6 MTR |

400 |

959 |

- |

|

152 |

115MM OD x 15.0MM THK x 6 MTR |

521 |

1251 |

- |

|

153 |

120MM OD x 12.0MM THK x 6 MTR |

400 |

959 |

- |

|

154 |

130MM OD x 15.0MM THK x 6 MTR |

461 |

1107 |

- |

|

155 |

150MM OD x 15.0MM THK x 6 MTR |

400 |

959 |

- |

|

156 |

190MM OD x 20.0MM THK x 6 MTR |

421 |

1010 |

- |

|

157 |

2"OD x 5.9MM THK x 6 MTR |

464 |

1114 |

- |

|

158 |

2"OD x 6.0MM THK x 6 MTR |

472 |

1133 |

- |